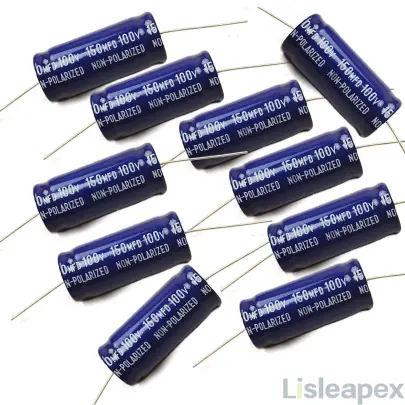

Non-polarized capacitors, also known as bipolar or unpolarized capacitors, stand as foundational components within the realm of electronic circuits. Unlike their polarized counterparts, non-polarized capacitors possess a unique characteristic – they lack the inherent positive or negative polarity typically associated with other capacitor types. This distinguishing feature allows for their seamless integration into circuits without the need for meticulous orientation, offering unparalleled versatility across a myriad of applications.

From AC coupling to audio processing and filtering, non-polarized capacitors serve as indispensable elements, facilitating efficient signal manipulation and circuit optimization. As we delve deeper into the intricate landscape of non-polarized capacitors, their multifaceted nature and paramount importance in modern electronics come to the forefront.

What is Non-polarized Capacitor(Definition)

A non-polarized capacitor, also known as a bipolar or unpolarized capacitor, is an electronic component devoid of positive or negative polarity markings, enabling it to be seamlessly integrated into a circuit in either orientation. Unlike polarized counterparts such as electrolytic or tantalum capacitors, which necessitate correct alignment due to their specific positive and negative terminals, non-polarized capacitors exhibit no such restriction and function effectively irrespective of their positioning.

These capacitors find extensive utility in applications characterized by fluctuating voltage polarities or alternating current (AC) environments. Commonly employed in AC coupling, audio processing, signal manipulation, and similar contexts where voltage directionality oscillates periodically, non-polarized capacitors offer versatility and reliability. Their inherent lack of polarity markings facilitates simplified integration and ensures operational efficacy, rendering them indispensable across diverse electronic circuits.

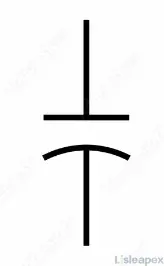

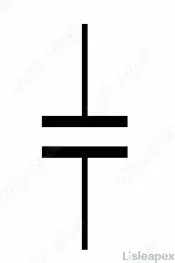

Non-polarized Capacitor symbol as below,

5 Types of Non-polarized Capacitor

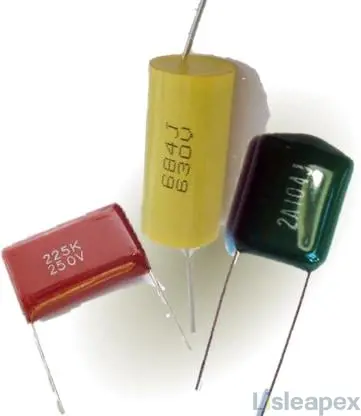

Non-polarized capacitors come in various types: electrolytic, ceramic, tantalum, mica, and film capacitors. They serve diverse functions in electronics, from high capacitance in electrolytics to stability in ceramics and safety in tantalums. Micas, once popular, are now less common, while films offer versatility in configurations like metalized and film/foil.

1) Electrolytic Capacitors: Electrolytic capacitors utilize an electrolyte solution and an oxide layer to create a large capacitance. When a voltage is applied, an electric field forms across the oxide layer, allowing for significant charge storage. They are commonly used in power supply filtering, audio circuits, and other applications requiring high capacitance values. However, they have polarity and must be connected in the correct orientation to avoid damage.

2) Ceramic Capacitors: Ceramic capacitors are made from ceramic materials with metal electrodes. They offer excellent stability, low leakage, and high reliability, making them suitable for use in various electronic devices. Ceramic capacitors come in different shapes and styles, such as ceramic disc capacitors and multi-layer ceramic chip capacitors (MLCCs), providing flexibility in circuit design. They find applications in coupling, decoupling, filtering, and timing circuits.

3) Tantalum Capacitors: Tantalum capacitors utilize tantalum metal as the electrode material, which forms a thin dielectric layer of tantalum oxide. This construction offers high capacitance density and stable electrical properties. Tantalum capacitors are prized for their reliability and long lifespan, making them ideal for use in critical electronic systems. They are commonly found in medical devices, telecommunications equipment, and automotive electronics.

4) Mica Capacitors: Mica capacitors use thin sheets of mica as the dielectric material, sandwiched between metal foil electrodes. Although they were once widely used, particularly in radio frequency (RF) circuits, their popularity has declined due to limitations in tolerance and stability. Mica capacitors are still occasionally used in niche applications where precise capacitance values and low losses are required.

5) Film Capacitors: Film capacitors employ a plastic or paper film as the dielectric material, with metalized or film/foil electrode configurations. Metalized capacitors have a metal layer deposited directly onto the dielectric film, offering self-healing properties and high capacitance. Film/foil capacitors use metal foils separated by the dielectric film, providing high surge current capability. They are used in a wide range of applications, including motor run capacitors, AC filtering, and audio signal coupling.

How to Use Non-polarized Capacitor

Connect the ends of the capacitor to the positive and negative terminals.

- For charge storage, connect the positive end to the positive terminal and the negative end to the negative terminal.

- For discharge, connect the negative end to the positive terminal and the positive end to the negative terminal.

Functions of Non-Polarized Capacitors:

- AC Coupling and Signal Blocking: Used to block DC components while passing AC signals in audio amplifiers.

- Decoupling and Filtering: Stabilize power supply voltages and filter out high-frequency noise in electronic devices.

- Tone Control and Equalization: Shape frequency response in audio circuits for preamplifiers and amplifiers.

- Audio Coupling and Filtering: Pass AC audio signals while blocking DC voltage, commonly used in amplifier stages.

- Tuning and Oscillation: Adjust frequency in oscillator circuits.

- Snubber Circuits: Suppress voltage spikes and transient effects in power electronics.

- Timing and Delay Circuits: Control timing intervals, such as in RC oscillators.

Application of Non-polarized Capacitor

The common applications of Non-polarized Capacitors are:

- Feedback Circuits

- Coupling Circuits

- Decoupling Circuits

- Oscillation Circuits

- Compensation Circuits

- Bi-directional Signal Transfer in Audio Applications

- AC Applications

Non-polarized capacitors play a crucial role in various electronic applications, particularly in pure AC circuits and high-frequency filtering due to their small capacitance.

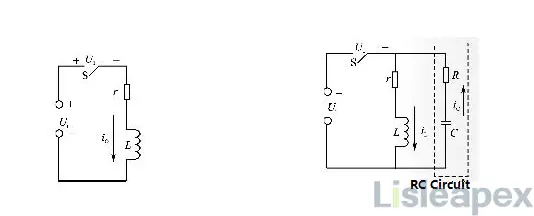

One significant application is the RC spark suppression circuit, where they are employed to mitigate electric sparks that occur when circuits with inductance are disconnected. In this scenario, the sudden interruption of current flow generates a large self-inductance, leading to a sharp voltage spike across the switch contacts. This spike can cause sparks, potentially damaging the contacts and disrupting circuit operation.

To prevent this, the RC spark suppression circuit is utilized, with the non-polarized capacitor connected at both ends of the inductor. When the switch is turned off, the capacitor charges and discharges, dissipating energy from the inductor and effectively eliminating the spark. Thus, non-polarized capacitors contribute to enhancing the reliability and safety of electronic systems by suppressing unwanted sparks in circuits with inductive components.

Pros and Cons of Non-polarized Capacitor

Pros of Non-polarized Capacitors:

- Versatility: Non-polarized capacitors can be connected in any direction, simplifying circuit design and installation.

- Wide Range of Applications: They are suitable for various circuit applications, including AC coupling, signal blocking, filtering, and audio applications.

- Compatibility: Non-polarized capacitors can handle both AC and DC signals, making them versatile for different circuit configurations.

- Reduced Risk: Their non-polarized nature reduces the risk of incorrect installation and damage compared to polarized capacitors.

- Stability: Non-polarized capacitors typically exhibit stable capacitance values over a wide range of frequencies and temperatures.

Cons of Non-polarized Capacitors:

- Limited Capacitance Range: Non-polarized capacitors generally have lower capacitance values compared to polarized capacitors, which may limit their use in certain high-capacitance applications.

- Size and Cost: Non-polarized capacitors may be larger in size and relatively more expensive compared to polarized counterparts with similar capacitance values.

- Voltage Limitations: They may have lower voltage ratings compared to polarized capacitors, which can restrict their use in high-voltage applications.

- Noise Susceptibility: Non-polarized capacitors may exhibit higher levels of noise compared to polarized capacitors in certain circuit configurations.

- Frequency Limitations: Some non-polarized capacitors may have limitations in handling

How to Choose a Suitable Non-polarized Capacitor

Selecting a suitable non-polarized capacitor involves several considerations to ensure optimal performance in the circuit. Here's a guide:

Accuracy: Choose a capacitor with an appropriate accuracy level, typically within 0.3% to 0.5% for oscillation, filtering, delay, and tone circuits.

Circuit Requirements: Select capacitors based on the specific needs of the circuit. Use paper capacitors for low-frequency AC bypass circuits and mica or ceramic capacitors for high-frequency or high-voltage circuits.

Rated Voltage: Ensure the capacitor's rated voltage exceeds or matches the actual requirements of the circuit.

Frequency Compatibility: High-frequency capacitors should not be substituted with low-frequency capacitors to maintain circuit functionality.

Operating Conditions: Consider factors such as operating temperature, working range, and temperature coefficient to ensure compatibility with the application environment.

Series or Parallel Connection: Utilize series or parallel connection methods as needed to achieve the desired capacitance and voltage ratings.

The Difference Between Non-polarized Capacitors and Polarized Capacitors

Non-polarized capacitors and polarized capacitors are distinct in their construction, operation, and applications. Non-polarized capacitors lack polarity, allowing for versatile connection orientations, while polarized capacitors require correct polarity for proper function. The table below provides a comprehensive comparison of their key differences:

|

Aspect |

Symbol |

Polarized Capacitors |

Non-Polarized Capacitors |

|

Symbol |

|

|

|

|

Polarity |

+ / - |

Requires correct polarity; reverse connection may damage |

No polarity; can be connected in any direction |

|

Voltage Ratings |

V |

Generally higher than non-polarized counterparts |

Typically lower |

|

Applications |

A |

Power supply filtering, audio amplification, voltage reg. |

AC coupling, audio processing, filtering |

|

AC and DC |

AC / DC |

Primarily used in DC circuits, requires consistent polarity |

Suitable for both AC and DC circuits |

|

Capacitance Value Range |

C |

Limited range, especially compared to non-polarized |

Various values and types available |

|

Size |

S |

Generally larger |

Diverse in size and form |

|

Temperature Characteristics |

T |

Performance may vary with temperature changes |

Varies based on materials; suitable selection available |

|

Suitable for Polarity Change |

P |

No; requires consistent polarity for proper operation |

Yes |

Conclusion

In conclusion, non-polarized capacitors emerge as pivotal components within electronic systems, embodying versatility, reliability, and efficiency in their design and functionality. Their ability to transcend the constraints of polarity orientation, coupled with a diverse array of dielectric materials and construction techniques, renders them indispensable across a broad spectrum of applications.

Whether employed in AC coupling circuits, audio processing modules, or power supply filtering networks, non-polarized capacitors play a foundational role in shaping the landscape of modern electronics. As technology continues to advance and new challenges emerge, the enduring relevance of non-polarized capacitors underscores their status as indispensable assets within the electronic engineer's toolkit.

FAQ

-

What Types of Dielectric Materials are Used in Non-polarized Capacitors?

Non-polarized capacitors can use various dielectric materials, including ceramic, polyester (Mylar), polypropylene, polystyrene, and tantalum. The choice of dielectric depends on factors such as capacitance value, temperature stability, voltage rating, and cost.

-

What Capacitance Values are Available for Non-polarized Capacitors?

Non-polarized capacitors are available in a wide range of capacitance values, from picofarads (pF) to microfarads (μF), depending on the specific application requirements. Capacitance values can vary based on the type of dielectric material used and the construction of the capacitor.

-

How do Non-polarized Capacitors Differ from Polarized Capacitors?

Non-polarized capacitors differ from polarized capacitors in that they do not have a fixed polarity. Polarized capacitors, such as electrolytic capacitors, have positive and negative terminals and must be connected in the correct polarity to avoid damage or failure.

-

Can Non-polarized Capacitors Replace Polarized Capacitors?

In some cases, non-polarized capacitors can replace polarized capacitors, depending on the circuit requirements and operating conditions. However, it is essential to consider factors such as capacitance value, voltage rating, temperature stability, and physical size when substituting capacitors.

-

Are Non-polarized Capacitors Available in Surface Mount (SMD) Packages?

Yes, non-polarized capacitors are available in surface mount (SMD) packages, making them suitable for modern electronics manufacturing processes. SMD non-polarized capacitors offer compact size, high reliability, and compatibility with automated assembly techniques.

Stay updated with Lisleapex by signing up for the newsletter

Congratulations On Your Successful Submission

Congratulations On Your Successful Submission

Submission Failure

Submission Failure