The Data We Archived:

- Brand

- RoHS & Lead-Free Status

- MFG Barcode Label Data

- Packaging Type

- Part Number And Marking

- Packaging Condition

- Wet Sensitivity Level (MSL)

- Date Codes

- Country/Countries Of Origin

- Intact Moisture Barrier Bag (MBB) Seals

All parts from our supply chain network undergo strict incoming inspections and are recorded to guarantee their authenticity upon delivery to our customers.

Our Testing Program:

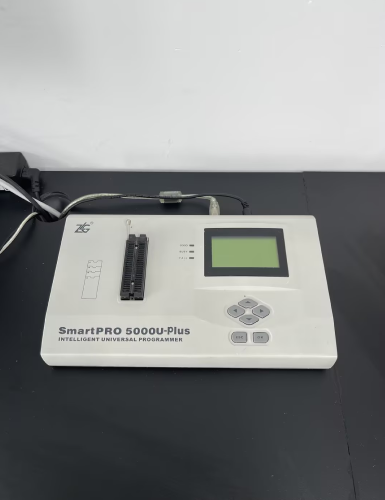

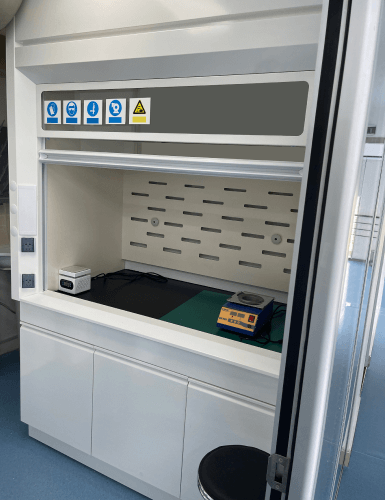

- Documentation and Packaging

- Inspection

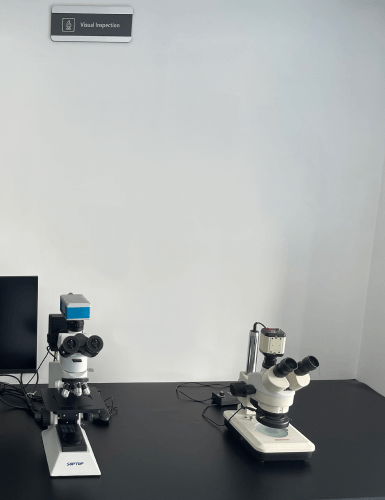

- External Visual Inspection

- Remarking and Resurfacing Inspection

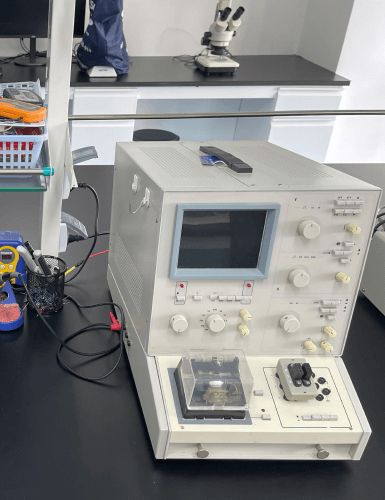

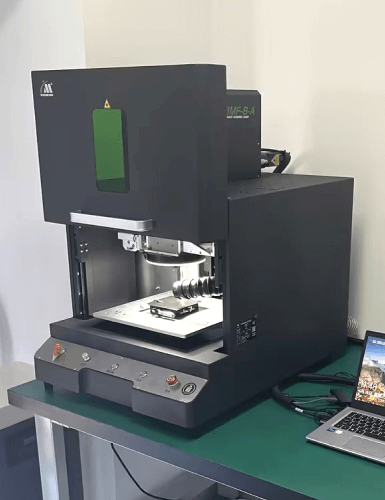

- X-Ray Inspection

- XRF/EDS

- Decapsulation

- Scanning Electron Microscope

- Quantitative Surface Analysis

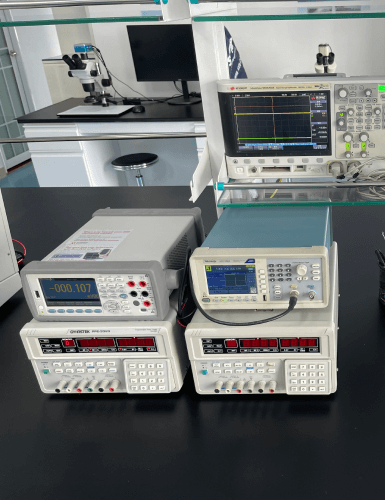

- Thermal Testing

- Electrical Testing

- Burn-In

- Hermeticity Verification

- Scanning Acoustic Microscopy

The parts we sell undergo a multi-step inspection by our quality inspection team before shipping to ensure they are free from quality issues caused by storage or other objective factors.

Internal Management Process:

Congratulations On Your Successful Submission

Congratulations On Your Successful Submission

Submission Failure

Submission Failure